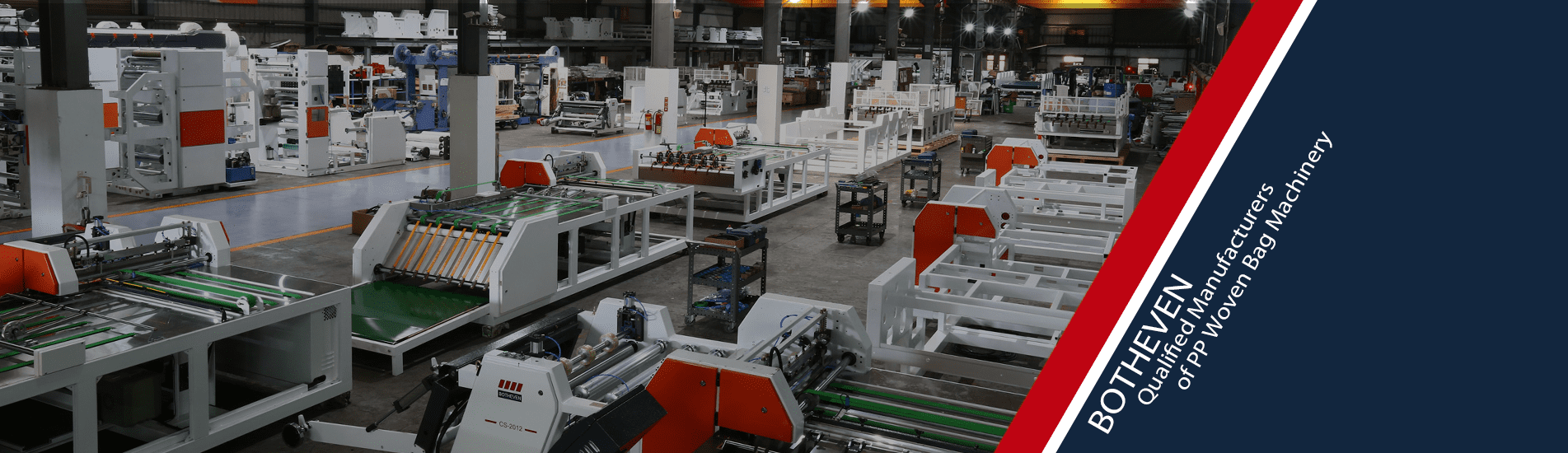

【AGENT WANTED!】Are You Interested In Being Our Agent? You're welcome to contact us

Products

Reel to Reel Printing Line NRP-2012/6C (New Developed Model)

- Imprint Arrangement 6+0, 5+1, 4+2, 3+3 colors combinations

- Production Output : 120 meter / min

-

Based on our original Reel to Reel Printing Line which had produced more than 10 years, we have further up-grade our machine. The New Reel to Reel Printing Line is a whole new design, the main improvements we need to emphasize are:

Equipped Gear Box on Each Printing Station, These Gear Box Can 360X Oline Print Registration While the Machine in Running.

Equipped Overhead Drying Oven. - Gear-Box equipped on each Printing Station, which, can perform online 360 rotation, in facilitating the conduct of micro adjustment required on individual station Imprint-Artwork Registration, under Non-Stop Operation.

- Enhanced Drying Efficiency for Quickly Drying

- Reel to Reel Printing Line is the most efficient way for the PP woven bag printing, and capable of two side printing on the bag in the one process, based on the current market demand, we are able to proide 12 colors(each side 6 colors) Reel to Reel Printing Line.

- Our Reel to Reel Printing Line provide the best printing quality with high output (up to 120 meter / minute) and only one operator required. Decreasing the printing cost to the lowest. It is the most wisdom choice for printing.

- Equipped Gear Box On Each Printing Station, These Gear Box Can 360° Online Print Registration While the Machine is Running.

- Enhanced Drying System for Quickly Drying

- Diameter of Unwinding Cloth 1200mm Maximum Applicable

- Width of Unwinding Cloth 350-850mm Applicable

- Printing Repeat Length 500-1300mm

- production Output 120 meters/minute Max.

- Ink Circulation Pump

- Corona Treater

- Auto Tension Controller

-

Air Shaft

-

Automatic Roll-Changing System

QUICK LINKS

CONTACT INFO

| No. 2-1, Fongchang St., Dapi Township, Yun-Lin County 631, Taiwan |

| +886-5-5916-970 |

| +886-5-5916-968 |

| [email protected] [email protected] |